Our 100,000 sqft, 12 acre site is home to the most knowledgeable and skilled engineers who work tirelessly to manufacturer an ever growing range of

products. Our range is manufactured to ISO 9002 with the finest tolerances. As a result of our achievements in the engineering sector, our clients

experience an unrivalled high quality product with flexible design.

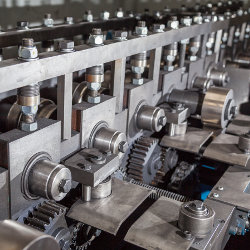

Roll Forming

In January 2015, BPL invested £350K in a brand new, state-of-the-art, fully automated Roll forming machine. This equipment will allow BPL to

produce the new sigma design cross-members utilised on the fusion upgrade as well as “U” channel sections and modular building profiles.

Other metal forming, joining and finishing capabilities

Punching and Pressing

BPL run state of the art turret punches to provide rapid throughput of sections with optimum flexibility in design. The turret punches are able to

produce blanks for parts in steel up to 4mm thick. Material usage is optimised in the CAM software, minimising waste and maximising value.

Press brakes with a capacity of 30 tonnes and a length of 6m enable the production of all but the longest sections.

Plasma Cutting

CNC plasma cutting extends the range of material thickness that may be cut beyond 4mm . Thick steel may be cut to virtually any profile required

using this equipment. As with the turret punches, material usage is optimised in the CAM software, minimising waste and maximising value.

Submerged arc welding and MIG

Submerged arc welding is used to rapidly produce long welds of good and repeatable quality to provide the best possible value. Where smaller or more

intricate welds are required, the versatility of MIG welding is adopted using the expertise of our experienced workforce.

For more information. Call 01964 545454 or email info@bankside-patterson.co.uk